Angst+Pfister Solutions Hub'a hoş geldiniz - mühendislik blogumuz ve makine ve endüstri mühendisliği konusunda uzman görüşlerine açılan kapı.

Angst+Pfister, yüksek performanslı sızdırmazlık, titreşim önleme ve sıvı taşıma çözümleri için özelleştirilmiş endüstriyel mühendislik çözümlerinde uzmanlaşmıştır. Yüzyılı aşkın deneyimimizle, teknik uzmanlık ve yenilikçi malzemeler aracılığıyla karmaşık zorlukları çözmeleri için endüstrilerdeki mühendislere güç veriyoruz.

Çözüm Merkezi, mühendisler ve teknik profesyoneller için bilgi platformumuzdur. Burada, PFAS içermeyen yenilikler ve mevzuat güncellemelerinden akıllı elastomerlere ve biyo-bazlı plastikler gibi sürdürülebilir çözümlere kadar en son endüstri konuları hakkında derinlemesine içerik bulacaksınız.

Uygulamalı mühendislik vaka çalışmaları, düzenleyici brifingler ve gerçek dünyadan örnekler aracılığıyla Çözüm Merkezi, mühendislerin ve teknik uzmanların karmaşık zorlukların üstesinden gelmelerine yardımcı olacak pratik bilgiler ve kanıtlanmış stratejiler sunar. “Bu Ayın Trendleri - Çözüm Merkezinde Öne Çıkanlar” bölümümüze göz atın ve sektörler arasında inovasyonu neyin yönlendirdiğini görün veya tüm blog yazılarımıza göz atın.

Sektörde trend olan başka bir konuyu veya uzman görüşlerini kaçırmayın.

Bu Ayın Trendleri - SolutionsHub Öne Çıkanlarımız

Blog yazılarımıza göz atın

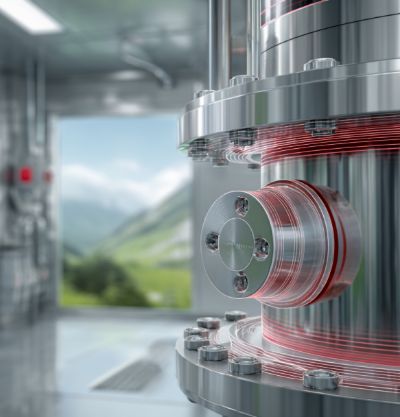

evolast® FFKM, aşırı direnç, tam uyumluluk ve tamamen Avrupa üretimi ile sızdırmazlık arızalarını önler.

Plastiğin CO₂ emisyonunu nasıl azaltabileceğini ve performansı nasıl koruyabileceğini keşfedinx

Güç aktarma sistemi uygulamaları için kaset contalarının dayanıklılık ve verimliliği nasıl sağladığını keşfedin.

Akıllı elastomerler, gerçek zamanlı izleme, öngörücü bakım ve verimlilik artırımı sağlar.

Maksimum hizmet ömrüne sahip paslanmaz çelik oluklu hortumlarla - LNG sistemlerini güvenli ve verimli bir şekilde çalıştırın

PFAS ile ilgili önerilen AB yönetmeliği polimer sızdırmazlık malzemelerini etkileyebilir. ECHA, floropolimerlerin sızdırmazlık teknolojisindeki önemini k ...

Gıda ve içecek endüstrisinde güvenli, uygun maliyetli plastik bileşenlerin zorluklarının üstesinden gelmek, orta ölçekli OEM'lerin bir yandan sıkı u ...

Angst+Pfister, EN45545 yangın yönetmeliğini karşılamada etkili çözümler sunar.

Yeni küresel PFAS yönetmelikleri PFAS içermeyen malzemeler için bastırıyor ve güvenilir tedarikçilerle işbirliğini teşvik ediyor

The choice of the optimum material guarantees unlimited coffee enjoyment.

Angst+Pfister'ın HITEC® DW EPDM elastomeri, yaklaşan KTW-BWGL içme suyu standartlarını karşılar ve aşarak üstün uyumluluk sağlar.

Angst+Pfister'ın PERTEC® UP EPDM bileşiği, küresel gıda ile temas yönetmeliklerini karşılayarak güvenli ve uyumlu contalar sağlar.

Angst+Pfister, hidrojen uygulamaları için elastomerleri titizlikle test ederek geleceğin enerji çözümlerine uygunluğunu garanti eder.

İşe yaramasını sağlıyoruz!

Sadece bizimle iletişime geçin ve size hızlı bir şekilde geri dönelim!

Güncel kalın!

Bugün bültenimize kaydolun ve ürünler ve en son endüstri trendleri hakkındaki en yeni güncellemelerimizi alın!