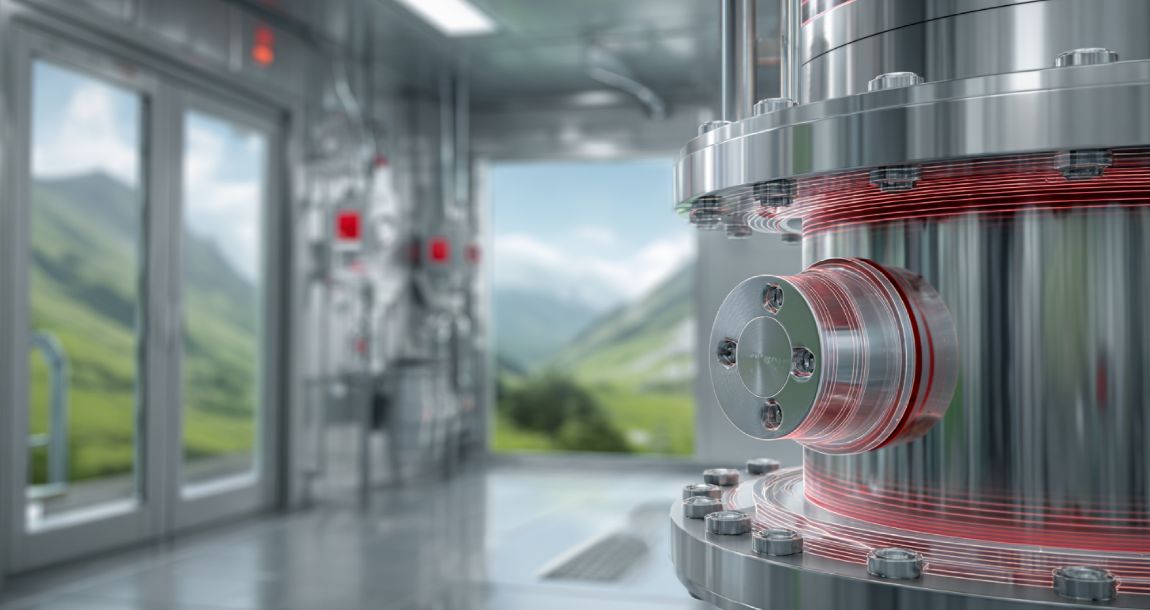

evolast® is the next generation of perfluoroelastomers. It combines the exceptional chemical and thermal resistance of PTFE with the elasticity and compression set resistance of elastomers. The result: Seals that withstand extreme temperatures — up to +340°C for premium grades — and a wider range of aggressive chemicals than conventional elastomers.

This makes evolast® the preferred choice for industries requiring high precision, durability, and consistent performance under demanding operating conditions. Key application areas include Chemical Processing, Pharma & Medical, Semiconductors, and Oil & Gas.

evolast® is 100% developed, compounded, and manufactured in-house at our Italian centers of excellence: TSF and MCM High-Performance Sealing. Complete control of the value chain – from material formulation to engineering and production – allows us to offer customized sealing solutions. This ensures short lead times and guarantees European quality and full traceability.

evolast® FFKM Key Facts and Figures

High thermal resistance – Wide temperature range from -46 °C to +340 °C

Over 30 available materials and endless customization possibilities

Cleanroom manufacturing and high-purity grades available

100% European-based production

Exceptional chemical resistance against acids, bases, solvents, plasma, and more

Trusted by leading players in the Chemical Processing, Pharma & Medical, Semicon, and Oil & Gas industries

Fully compliant with FDA, USP Class VI, EU 1935/2004, NORSOK, NACE, ISO 23936-2, API 6A, and more

One integrated partner for compounding, engineering, production, and supply chain

evolast® FFKM Solutions

We offer a wide range of components for both static and dynamic sealing applications. They are available in standard as well as customized geometries and dimensions.

Simple geometry and high sealing performance.

Special geometry, engineered for special sealing applications.

Fort stamped parts productions.

Which Industry Are You In?

evolast® FFKM for the Chemical Process Industry

Processing Challenges

- Aggressive Chemicals: Many chemicals degrade standard elastomers, e.g., acids, solvents, and caustics.

- High Temperatures: Reactors, distillation, and cleaning processes often exceed +200°C.

- Frequent Cycling: Pressure and temperature cycling can lead to seal fatigue and leakage.

- Downtime Costs: Unscheduled maintenance due to seal failure is extremely costly.

Benefits of evolast® FFKM

- Exceptional Chemical Resistance: evolast® handles corrosive media that destroy conventional elastomers.

- Thermal Stability: evolast® delivers consistent sealing at elevated process temperatures of up to +340 °C.

- Seal Integrity: Withstands cycling without cracking, shrinking, or loss of elasticity.

- Operational Efficiency: Reduces unplanned stops and lowers total maintenance costs.

- Process Safety: Protects equipment and environments by preventing critical leaks.

evolast® FFKM Compound Table Chemical Process Industry

| evolast® Compound | Shore A | Colour | Service Temperature Range | Suggested Applications | Remarks / Approvals |

|---|---|---|---|---|---|

| PN894 | 75 | black | -25°C to 275 °C | Excellent choice for use in aggressive chemical environments, providing a broad chemical resistance to different media such as acids, bases, water, steam, amines, solvent based chemistries. It is recommended as a multipurpose compound in all applications where fluid handling of different substances is required due to its excellent chemical resistance to a wide range of chemicals. Ideal for valves, pumps, mechanical seals, sprayers, compressors, reactors. | |

| PN896 | 75 | black | -15°C to 330 °C | For a wide operational temperature range without compromising chemical resistance in valves, pumps, mechanical seals, sprayers, compressors, reactors. resistance in valves, pumps, mechanical seals, sprayers, compressors, reactors. Excellent choice for use in aggressive chemical environments, when thermal resistance is also required, exhibiting outstanding high temperature stability and low compression set. | |

| PN775 | 75 | black | -15°C to 340 °C | For use with aggressive chemicals, not suitable for steam and amines. High temperature capability and a low compression-set at continuous temperature up to 320°C. | |

| PN7LT | 75 | black | -46°C to 250 °C | Designed specifically for chemical process industry where ultra low temperature capabilities are required. Excellent choice for use with aggressive chemicals, acids, bases, steam, amines, organic and inorganic media. | |

| PN8SR | 75 | black | -15°C to 330 °C | For steam and hot water resistance. Statical short time up to +340°C. | |

| PN897 | 80 | black | -30°C to 260 °C | Chemical process industry at low temperatures. Well suited for use in a wide range of applications from mechanical seals to pump housing. | |

| PN7HC | 70 | black | -20°C to 260 °C | Suitable for steam, hot water, amine. | |

| PB694 | 60 | white | -20°C to 270 °C | Made with FDA compliant elastomer. Provides superior chemical resistance and low contamination extractables for Pharmaceutical, Medical and Food & Beverage handling applications. | "According to FDA, USP Class VI 3A Sanitary Standard" |

| PN694 | 60 | black | -25°C to 270 °C | Excellent choice for use with aggressive chemicals, acids, bases, steam, amines, organic and inorganic media, methanol, TBA and MTBE, esters, ethers. | |

| PN994 | 90 | black | -30°C to 260 °C | Ideal for high pressure and low temperature applications. High hardness and high molecular weight reduce the possibility of gap extrusion. |

evolast® FFKM for the Pharma and Medical Industry

Processing Challenges

- Sterilization Stress: Frequent SIP, CIP, and autoclaving degrade conventional elastomers.

- Contamination Risk: Poor-quality seals can release extractables and leachables.

- Compliance Pressure: Seals must meet FDA, USP Class VI, and EU 1935/2004 standards.

- Batch Loss: Seal failure can lead to costly product contamination and wasted batches.

Benefits of evolast® FFKM

- Purity & Biocompatibility: Ultra-low extractables for safe contact with APIs, biologics, and excipients.

- Sterilization Resistance: Withstands repeated exposure to steam, chemicals, and high temperatures.

- Regulatory Confidence: Fully compliant with global pharma and medical standards.

- Process Reliability: Minimises downtime and ensures product integrity across batches.

- Traceability: Validation-ready materials with full documentation and manufacturing transparency.

evolast® FFKM Compound Table Pharma and Medical Industry

| evolast® Compound | Shore A | Colour | Service Temperature Range | Suggested Applications | Remarks / Approvals |

|---|---|---|---|---|---|

| PB694 | 60 | white | -20°C to 270 °C | Made with FDA compliant elastomer. Provides superior chemical resistance and low contamination extractables for Pharmaceutical, Medical and Food & Beverage handling applications. | - According to FDA, USP Class VI - 3A-Sanitary Standard |

| PB7LT | 70 | white | -40°C to 250 °C | Designed specifically for applications where low temperature capabilities are required. An excellent choice for use with aggressive chemicals, acids, bases, steam, amines, organic and inorganic media. Ultra low temperature. | - Acc. to FDA, USP Class VI - 3A-Sanitary Standard. |

| PN697 | 60 | black | -40°C to 260 °C | Ultra low temperature. | - FDA CFR 1772400, FDA CFR 177.2600 |

| PB795 | 70 | white | -15°C to 300 °C | For valves, pumps, mechanical seals, sprayers, biomedical equipment, food equipment, fermenters. High temperature. | - According to FDA, USP Class VI - 3A-Sanitary Standard |

| PB895 | 80 | white | -15°C to 300 °C | For high temperature applications in Pharma, Food & Beverage. | - According to FDA, USP Class VI - 3A-Sanitary Standard |

| PB794 | 70 | white | -20°C to 270 °C | For valves, pumps, mechanical seals, sprayers, biomedical equipment, food equipment, fermenters. | - FDA 21CFR177.2400, FDA 21CFR177.2600 USP Class VI, 3A-Sanitary Standard Reg. EC 1935/2004, DM 21/03/1973, BfR XXI |

| PN794 | 70 | black | -25°C to 270 °C | For high temperature in Food & Beverage within valves, pumps, mechanical seals, sprayers, compressors, reactors. | - FDA21 CFR 177.2400, FDA21 CFR 177.2600, 3A-Sanitary Standard, USP Class VI |

evolast® FFKM for the Semiconductors and Electronics Industry

Processing Challenges

- Plasma Resistance: Reactive gases in etching and deposition chambers degrade standard seals.

- Contamination Risk: Outgassing and particle shedding can damage sensitive wafers.

- Vacuum Demands: Conventional elastomers struggle in ultra-clean, high-vacuum environments.

- Microleakage: Tiny leaks can cause defects in high-precision processes.

Benefits of evolast® FFKM

- Extreme Plasma & Chemical Resistance: Engineered for outstanding durability, especially in fluorine-rich and reactive environments.

- Ultra-Low Outgassing: Minimizes particle release to protect wafer integrity.

- Vacuum Compatibility: Special FFKM grades perform reliably in cleanroom and vacuum conditions.

- Process Stability: Reduces contamination and failures to improve yield and extend uptime.

evolast® FFKM Compound Table Semiconductors and Electronics Industry

| evolast® Compound | Shore A | Colour | Service Temperature Range | Suggested Applications | Remarks / Approvals |

|---|---|---|---|---|---|

| PS152 | 75 | black | -25°C to 275 °C | Filling machines, wafer preparation, photolithography. To maintain product purity, the seals are manufactured and packaged in a cleanroom environment. | Outstanding resistance to chemicals, including organic and inorganic acids, alkalis, esters, ethers, ketones, and aldehydes, it excels in harsh wet chemical processes. |

| PS221 | 75 | amber | -15°C to 275 °C | Gas inlet seals, gas orifice seals, gas feedthrough seals, other plasma applications, other static and low stress/low sealing force applications. To maintain product purity, the seals are manufactured and packaged in a cleanroom environment. | |

| PS251 | 75 | black | -15°C to 340 °C | Center ring seals, chamber seals, fittings, plenum seals, quartz tube seals. To maintain product purity, the seals are manufactured and packaged in a cleanroom environment. | |

| PS321 | 65 | amber | -15°C to 275 °C | Gas inlet/orifice seals, chamber lid seals, isolation valve seals, photolithography. To maintain product purity, the seals are manufactured and packaged in a cleanroom environment. | Specifically designed for semiconductor plasma and gas deposition processes. Low outgassing and minimal metal content. |

| PS342 | 65 | brown | -15°C to 325 °C | Gas inlet/orifice seals, chamber lid seals, isolation valve seals. To maintain product purity, the seals are manufactured and packaged in a cleanroom environment. | |

| PS343 | 75 | brown | -15°C to 325 °C | Gas inlet/orifice seals, chamber lid seals, isolation valve seals. To maintain product purity, the seals are manufactured and packaged in a cleanroom environment. | |

| PS341 | 75 | dark green | -15°C to 330 °C | Gas inlet/orifice seals, chamber lid seals, isolation valve seals. To maintain product purity, the seals are manufactured and packaged in a cleanroom environment. |

evolast® FFKM for the Oil & Gas Industry

Processing Challenges

- High Pressure & High Temperature (HPHT) Conditions: Subsea and downhole environments combine extreme pressure and temperature.

- Sour Gas Exposure: H₂S and CO₂ degrade conventional elastomers over time.

- Mechanical Stress: High vibration, compression, and extrusion risks challenge seal integrity.

- Strict Compliance: Safety and environmental standards demand reliable, high-performance sealing.

Benefits of evolast® FFKM

- Chemical & Pressure Resistance: Performs reliably under HPHT and sour gas conditions with minimal degradation.

- Mechanical Durability: Withstands thermal cycling and mechanical loads in critical components like wellheads, pumps, and valves.

- Extended Service Life: Reduces maintenance needs and helps prevent leakage or blowouts.

- Operational Safety: Supports compliance and integrity in high-risk environments.

evolast® FFKM Compound Table for the Oil & Gas Industry

| evolast® Compound | Shore A | Colour | Service Temperature Range | Suggested Applications | Remarks / Approvals |

|---|---|---|---|---|---|

| PN9LT | 90 | black | -46°C to 250 °C | For valves, pumps, drilling tool, wellheads, turbines. Excellent mechanical and sealing properties. |

|

| PN9EX | 90 | black | -15°C to 320 °C | High temperature applications for valves, pumps, drilling tool, wellheads, turbines. Excellent mechanical and sealing properties. |

|

| PN9ED | 90 | black | -15°C to 260 °C | For valves, pumps, drilling tool, wellheads, turbines. Excellent mechanical and sealing properties. |

|

Related Downloads

Catalogue with technical information and basic knowledge on evolast® FFKM.

Discover Our Engineering Capabilities

.png)

We use CAD and Finite Element Analysis to design, validate, and optimize products efficiently..

With customized material formulations we ensure high performance solutions.

.jpg)

We ensure product durability through advanced solution testing and validation.

Our global production network utilizes advanced manufacturing technologies.

We provide local technical support in 24 countries.

We make it work!

Just contact us and We will get back to you as quickly as possible!

Your one-stop shop for industrial components

Dive into the extensive range of standard applications in the online shop of APSOparts with great benefits for efficient order processes!