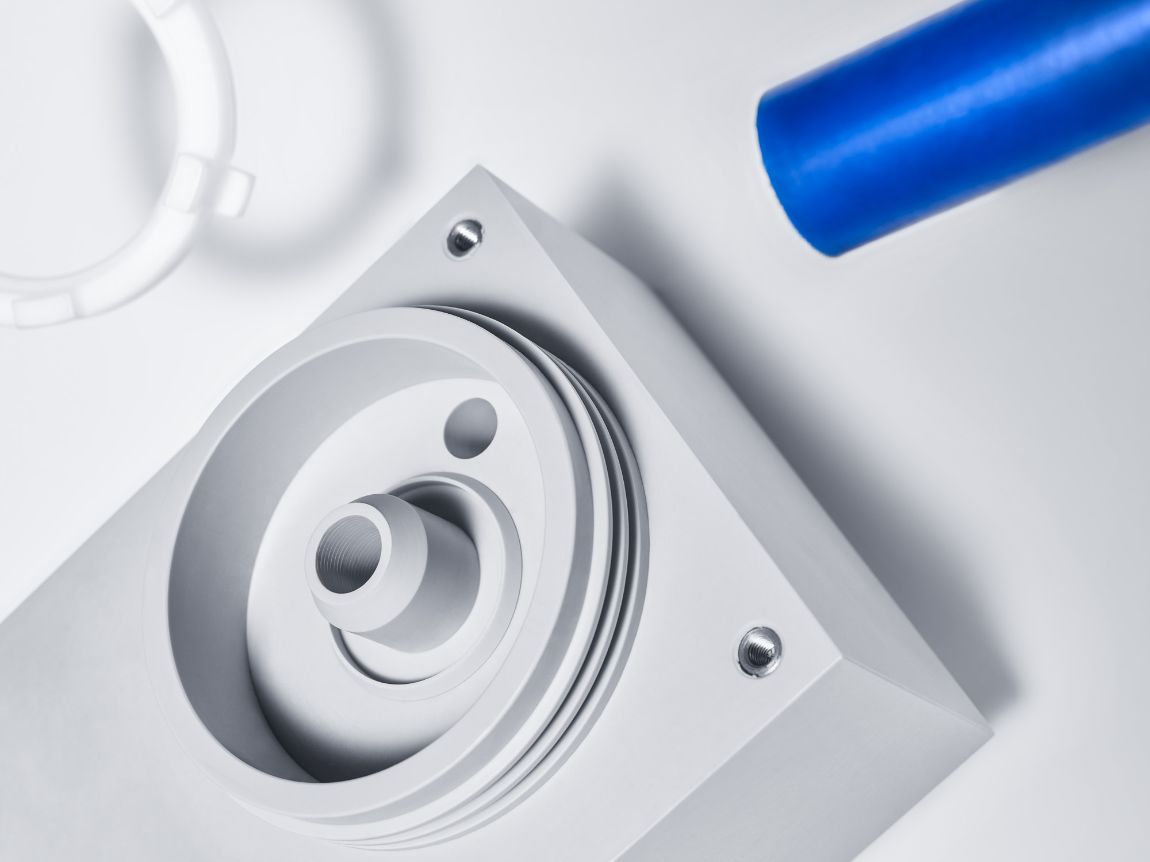

We Are Your Partner for Custom Plastic Parts

The Ideal Processing Technique

We supply parts according to your drawings, machined and ready for installation, from all plastics of our company on CNC-controlled turning and milling machines. Our know-how, even for materials that are difficult to machine, ensures the production of tolerance-bearing parts. In addition, we provide complete assemblies, including the corresponding installation.

GMP Certificate (Good Manufacturing Practice)

Plastics meet Food & Beverage

The Angst+Pfister Group was one of the first companies in the industry to be awarded the GMP (Good Manufacturing Practice) certificate for the production of plastic parts for devices with food contact surfaces (EFCF) by the globally recognized DNV-GL Business Assurance Group. This certification applies specifically to the production of machined plastic parts and cuts from semi-finished plastics, which comply with EU 10/2011, and are intended for direct contact with food in food processing and packaging machinery and equipment.

For applications in the food industry and medical technology, we offer all required product conformities and approvals such as FDA, EC 1935/2004; EU 10/2011, ISO 10993.

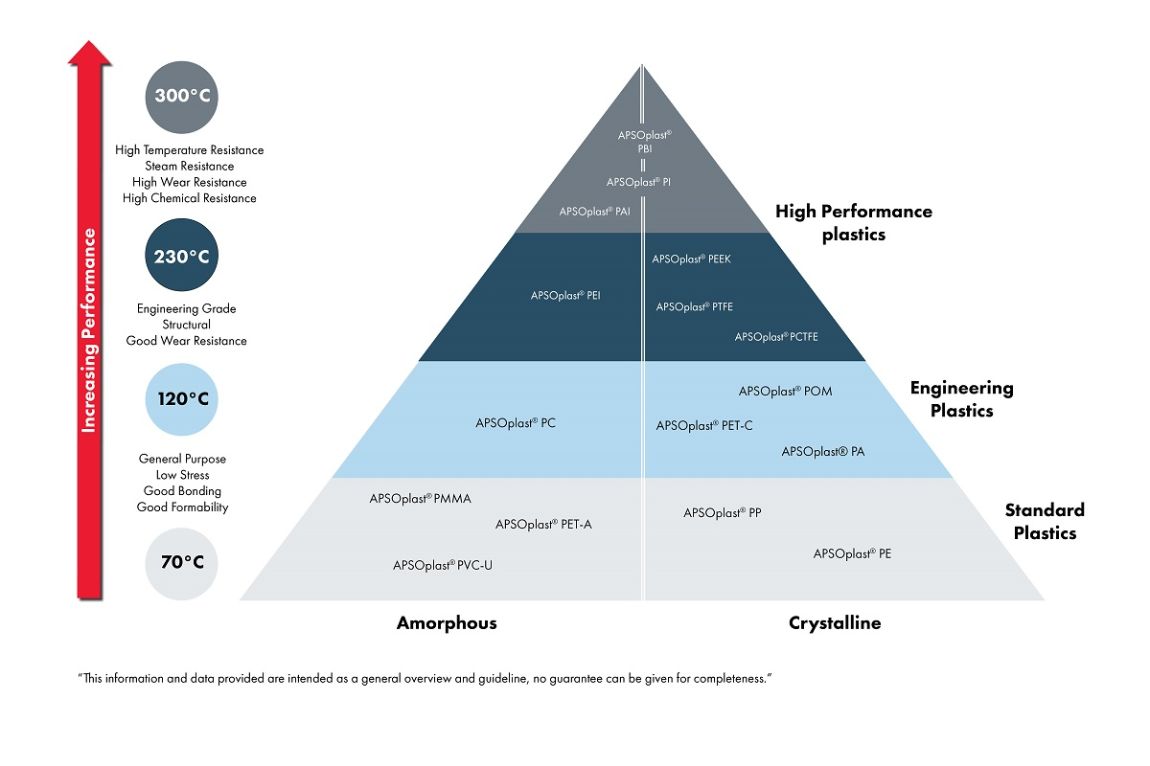

The Right Plastic Product for Every Application

Materials Matter

Angst+Pfister has an extensive range of plastics that covers all the requirements needed in the market. We are particularly strong in the field of technical and high-performance plastics, such as PEEK, PAI, PEI, or VESPEL, which are used primarily in the high-temperature range. But we also offer a wide range of fluoroplastics, especially PTFE, also known as Teflon. All relevant thermoplastics and duroplastics are also available from us in various forms.

If you are interested in deeper information on our sealing compounding, consult our product lists:

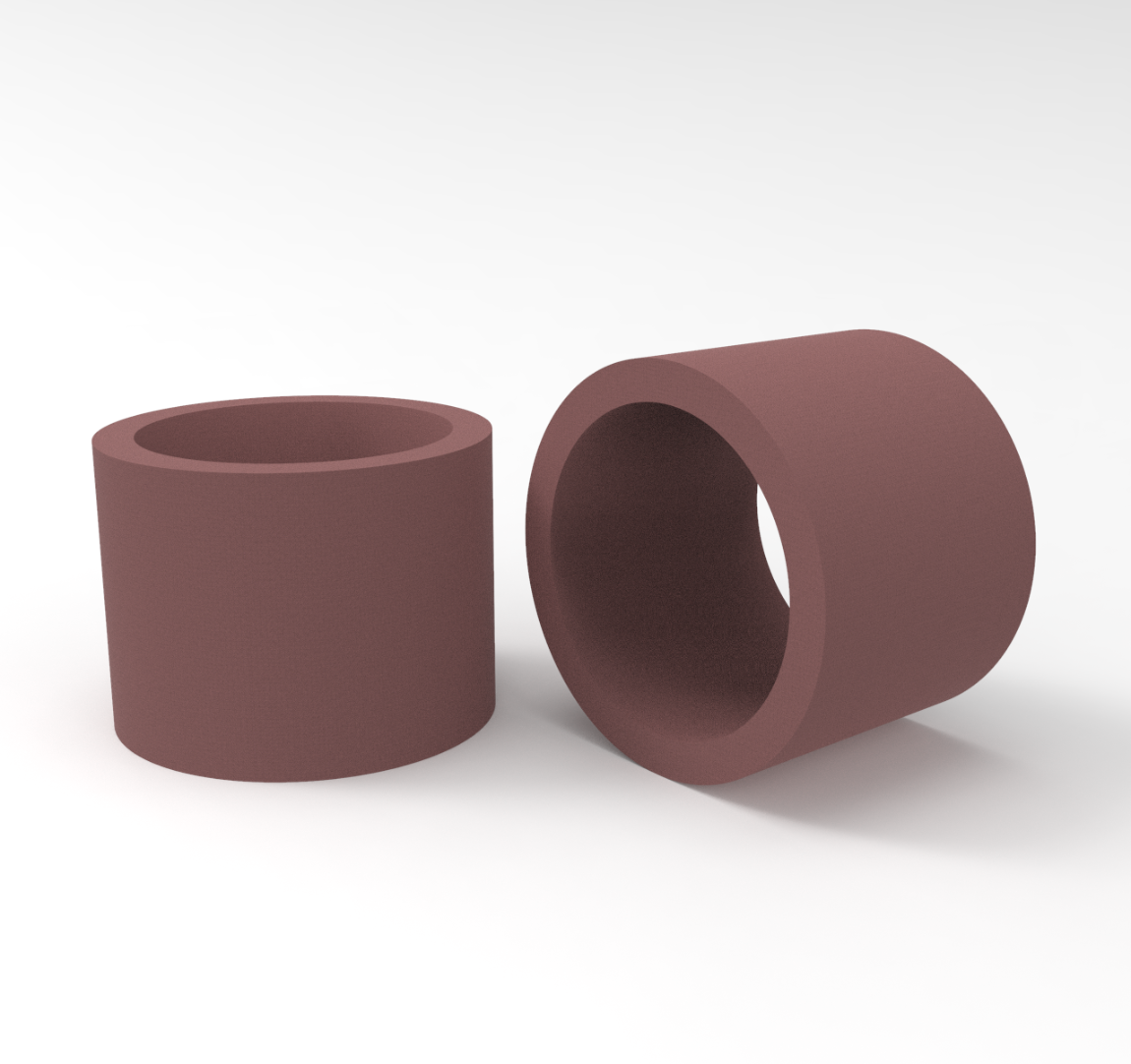

Smooth Moves: Our Diverse Array of Bushings and Bearings

Plain Bearing Bushes

In this area, we provide a large assortment of different bearing bushes with and without a collar. Our standard range includes high-performance plastics such as galvanized PTFE, PTF HP108, modified PET-C variants, and polyamide 66.

They are typically applied as axial-radial bearings for rough, low-wear operation (e.g., for lever and hinge bearings), as guides for rotating shafts in machine and vehicle construction, and also in dry running operation as electrically insulating bushings for flange bolts. Our bearing bushes are used for sliding, rotating, lifting, or pivoting movements. The plain bearings can be used at low speeds in machines and constructions.

The ideal solution for use in mechanical and apparatus engineering, in drive technology, and in vehicle construction can be found in our range of plain bearings.

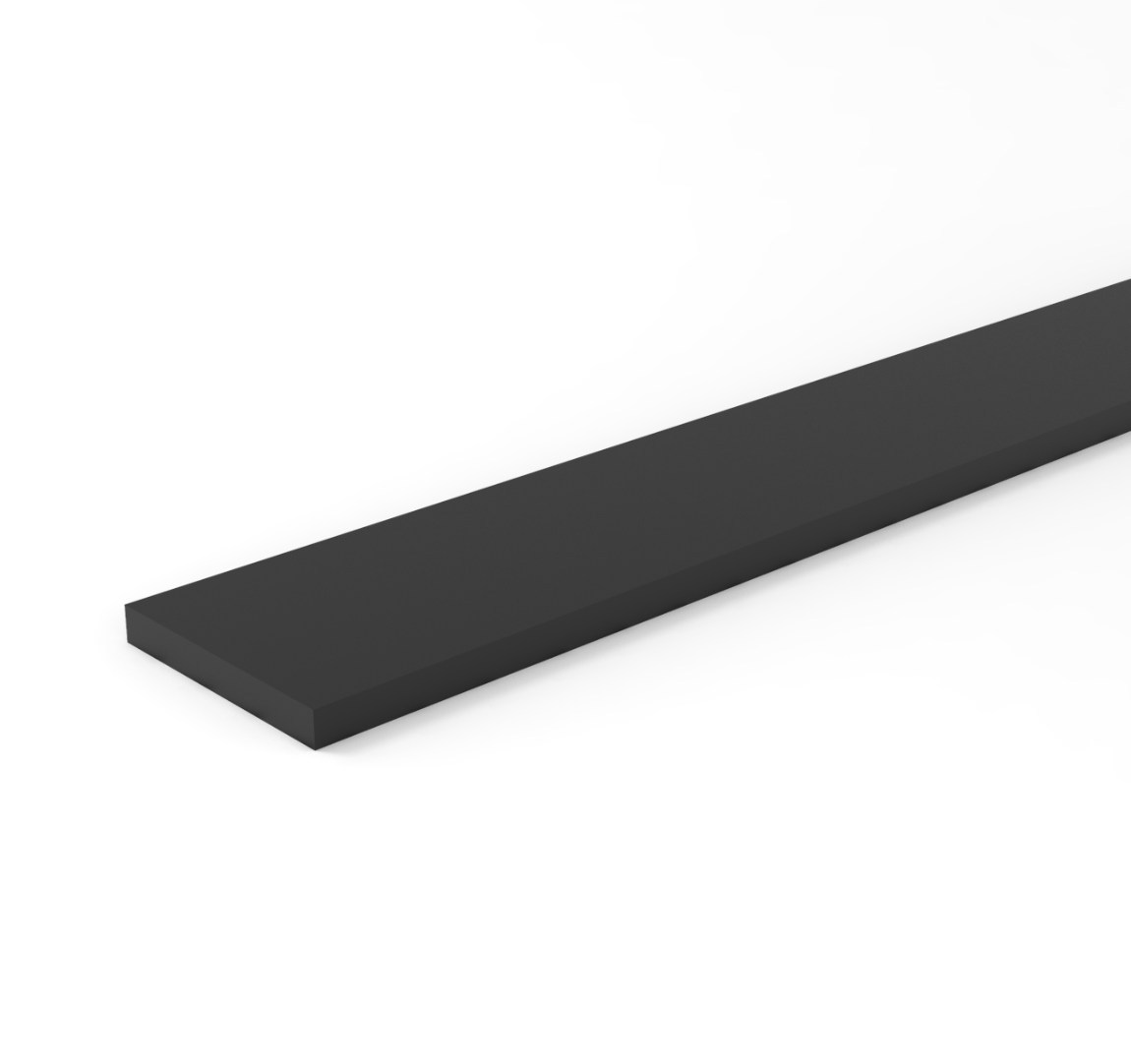

Guide Tapes

Guide tapes are a perfect fit for backlash-free guidance of pistons and piston rods in hydraulics, as well as for cost and space-saving storage of lubricated pivots and shafts (e.g., for levers with swivel movements). With our high-performance fluoroplastic, there are no limits to the application. PTFE 225, PTFE 660, and PTFE 904 offer many advantages, such as a no-stick-slip effect, extremely low coefficient of sliding friction, excellent chemical resistance, and a wide temperature range.

Our guide tapes are suitable for a very wide range of applications, such as for play-free bearing of shafts and pivots in chemical apparatus engineering. They can be used for slow rotational, swivel, and lifting movements.

Foil Bearings

Our foil bearings made of high-performance PTFE compounds offer an extremely low coefficient of sliding friction, high wear resistance, extreme high and low temperature resistance, as well as excellent chemical resistance.

Our foil bearings can be used as floating bearings in bore or shaft grooves, as very wear-resistant, clearance-free bearings for shafts, rods, and trunnions, and of course much more. They are suitable for rotation and stroke movements in dry running conditions.

Which industry are you in?

Our Key Industries we serve for Engineering Plastics Solutions.

Let’s Talk about your Project!

Request a Free Consultation and Find a Perfect Solution Customized for you.

Based on our assortment, we create and develop an individual solution for your application – or we even develop from scratch a high-performance part for your product to ensure quality & safety. For expert advice and customized solutions tailored to your specific needs, Angst+Pfister's service offerings are your go-to resource in engineering plastics solutions.

Let's talk!