Working with Angst+Pfister means

High-Quality Standard Fittings

Discover a range of fittings, including pipe sockets, nipples, flat sealing fittings, 24° fittings, welding neck flanges, and collar loose flanges. Our product line extends to special fittings, compensators, pipes, and customized solutions for complete system integration.

Comprehensive Certifications

ASSIWELL® hose lines adhere to rigorous standards, including:

- 97/23/EG Pressure Equipment Directive (PED), Category I and II, Module A1 Swiss TS

- DIN EN 15085-2 Railway Applications – Welding of Rail Vehicles, Certification Level CL1 Swiss TS

- DIN 3384 Stainless Steel Gas Hose Lines According to DVGW and SVGW

- TPW/W 119-1 Design and Testing of Corrugated Hose Connections for Water Installations

- TPW 119 Design and Testing of Flexible Connections for Water Installations according to SVGW

Own Production Capabilities

With production facilities in 15 countries, we provide a cost-effective and globally oriented environment, ensuring we meet quantity, logistics, and quality requirements.

How our solutions make a difference

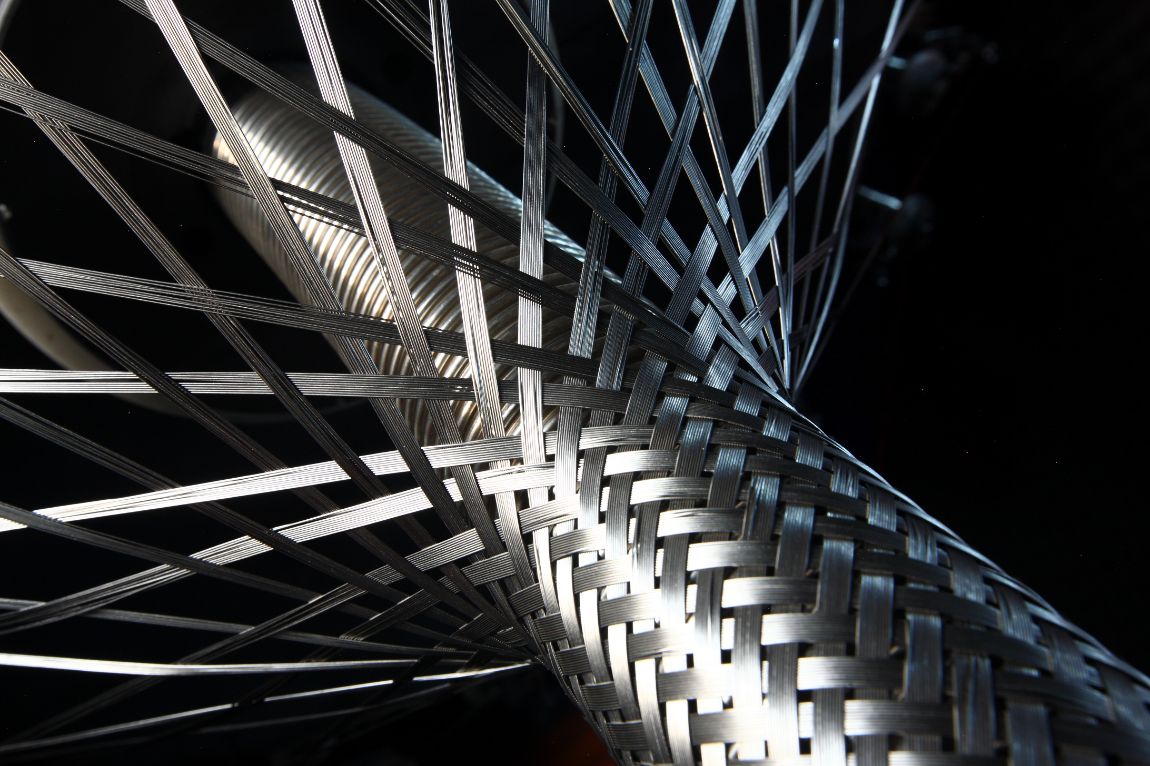

Customized Metal Hose Solutions

With decades of experience in various industries, Angst+Pfister provides competent, flexible, and swift support during the construction phase. Benefit from our expertise in electrical and mechanical engineering, the steel industry, measurement and control technology, building technology, energy industry, railway industry, and automotive industry. Contact us with your individual needs for optimized solutions

Your Complimentary Guide on Metal Hoses Awaits!

Would you like to explore further into the world of Metal Hose Solutions? Then download our complimentary technical guide on this subject for free.

Let’s Talk about your Project!

Request a Free Consultation and Find a Perfect Solution Customized for you.

Based on our assortment, we create and develop an individual solution for your application – or we even develop from scratch a high-performance part for your product to ensure quality & safety. For expert advice and customized solutions tailored to your specific needs, Angst+Pfister service offerings are your go-to resource in metal hose solutions.

Let's talk!