We are your qualified partner for engineering solutions, offering a wide range of high-performance components designed to meet your specific requirements in your industry of interest. Our commitment to providing innovative solutions is reflected in our deep technical expertise and collaborative problem-solving approach.

Innovative Solutions for over a Century

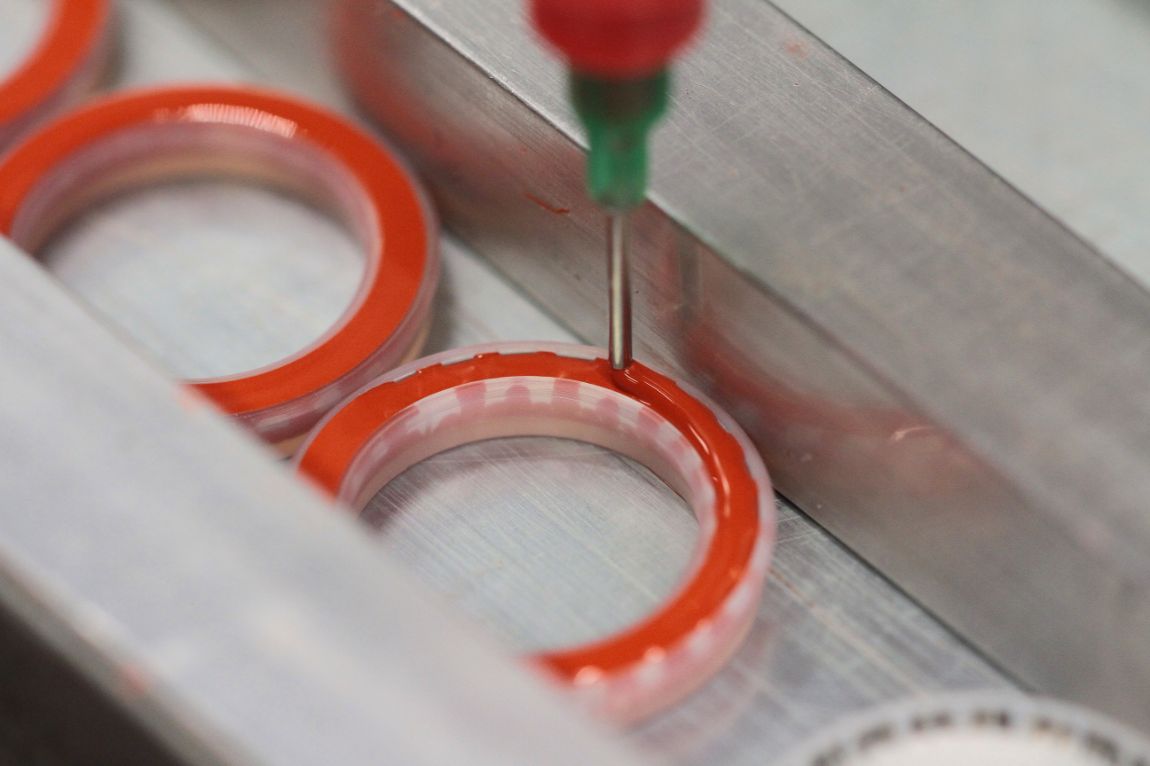

Sealing Solutions

In the field of Sealing Technology, our developers have been a pioneering force for over 100 years. From our humble beginnings as a local Swiss company, we have evolved into a leading international provider of sealing solutions. Our extensive range of solutions includes Elastomeric Compounds, O-rings and Molded Solutions, Rotary & Linear Seals. As your innovation development partner, we guide you through the entire value chain – from application evaluation, material design, prototyping, testing, to series production and delivery.

Let's talk!

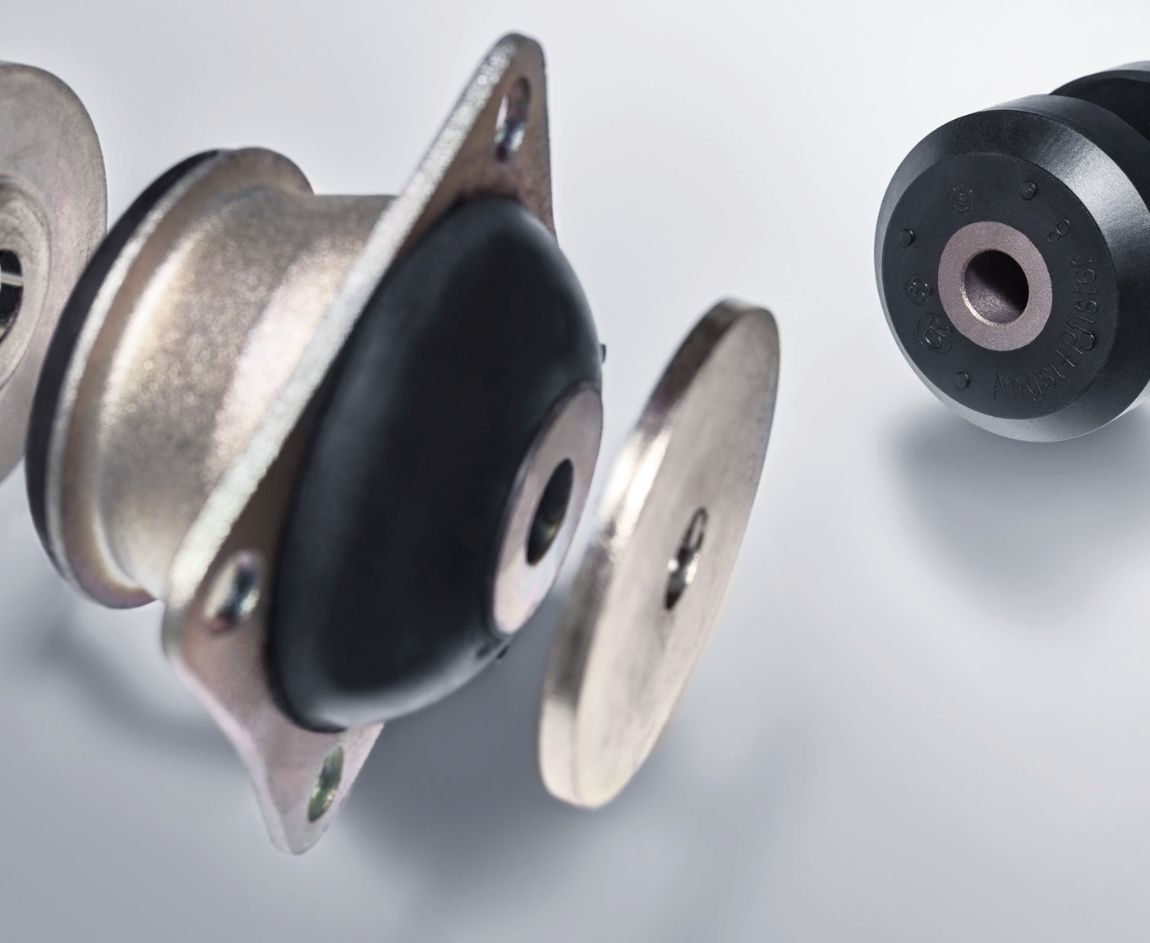

Reduce noise for optimal performance

Antivibration Solutions

Vibrations generated by machines and plants can be disruptive and, in some cases, even hazardous to health. Angst+Pfister addresses this challenge by offering a range of Antivibration Technology Products. By integrating the most suitable insulation elements during the initial design phase, we help counteract disturbances, ensuring optimal system performance.

Find out more

Comprehensive Product Segments to Meet Your Needs

Explore our solutions now, and discover how Angst+Pfister's components can make a significant difference in your applications.

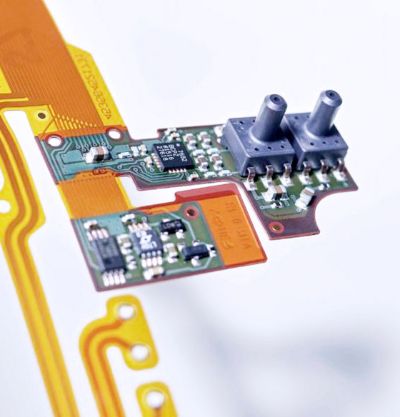

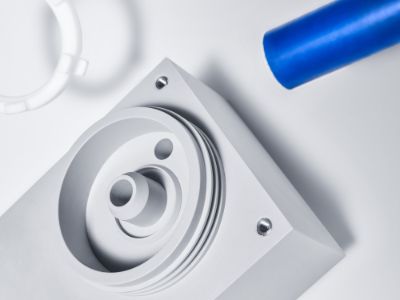

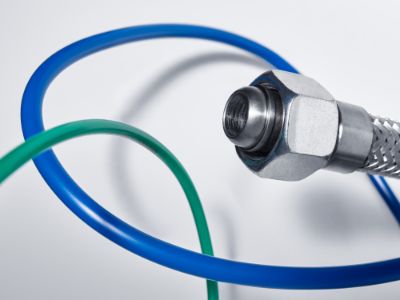

While our focus remains on Elastomeric Compounds -, O-Rings & Molded Solutions, Rotary & Linear Seals Solutions, and Antivibration Solutions, we don't stop there. Angst+Pfister is your go-to partner for a wide array of products, including Plastic Technology Solutions, ASSIWELL Hoses Solutions, Fluid Handling Solutions, Mechanical Drive Solutions, and Sensors and Power Solutions. Our goal is to provide industry-leading components that seamlessly merge into novel technologies, ultimately reducing the total cost of ownership and accelerating the time-to-money process for our clients.

At Angst+Pfister, we stay ahead of the curve in Engineering Plastics Technology. We offer a comprehensive range of services for practically every applica ...

Boost connectivity with ASSIWELL® metal hoses and stainless steel fittings, spanning -270°C to +600°C.

Discover tailored solutions and efficient components for diverse fluid applications, backed by expertise and a commitment to prompt delivery

Innovative design parts for enhanced performance, efficiency, and cost savings, backed by over 30 years of drive technology experience at Angst+Pfister