We make it work!

Strong partnerships and engineering capabilities create value.

“We have to put our customers first. Always.”

Jacques Angst

A true partnership means using synergies with resources and expertise so efficiently that both can benefit and grow. We have the great privilege of experiencing this time and time again. See for yourself.

Proven Success in Motion - Our Customer Stories

AMZ Racing and Angst+Pfister collaborated to develop an innovative suspension system.

EPFL Racing Team and Angst+Pfister collaborated to enhance Formula Student car.

Alphorn maker Bruno Cattaneo and Angst+Pfister collaborated to enhance instrument's assembly.

Eversys and Angst+Pfister collaborated to develop compact, efficient coffee grinding technology.

LAG Trailers and Angst+Pfister partnered to enhance food-approved sealing solutions.

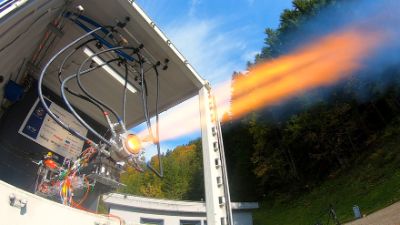

ARIS students partnered with Angst+Pfister for rocket's critical sealing solutions.

Franke and Angst+Pfister co-developed space-saving dampers to reduce coffee machine vibrations.

Coperion and Angst+Pfister co-developed a cost-effective, hygienic silicone cover.

.jpg)

Angst+Pfister engineered custom vibration dampers for BMW's S 1000 RR motorcycle.

Angst+Pfister collaborated with South Korea's Dawonsys on antivibration components.

Quivogne and Angst+Pfister collaborated to enhance disc harrow durability.

MCM S.p.A collaborated with Starline to develop hydrogen-resistant valve seals.

Angst+Pfister developed custom seals for Krone’s pellet harvester machinery.

We make it work!

Just contact us and We will get back to you as quickly as possible!

Stay up-to-date!

Sign up for our newsletter today and receive our newest updates on products and latest industry trends!