Connect on LinkedIn

Key Facts at a Glance

.png)

The shift to electric and hybrid drivetrains is redefining how vehicles are designed, built, and experienced. With higher demand for noise, vibration harshness, and the increasing reduction of compact architectures, traditional solutions for vibration and load control are being pushed to their limits.This development demands smarter components that can balance performance, durability, and efficiency without adding unnecessary complexity.

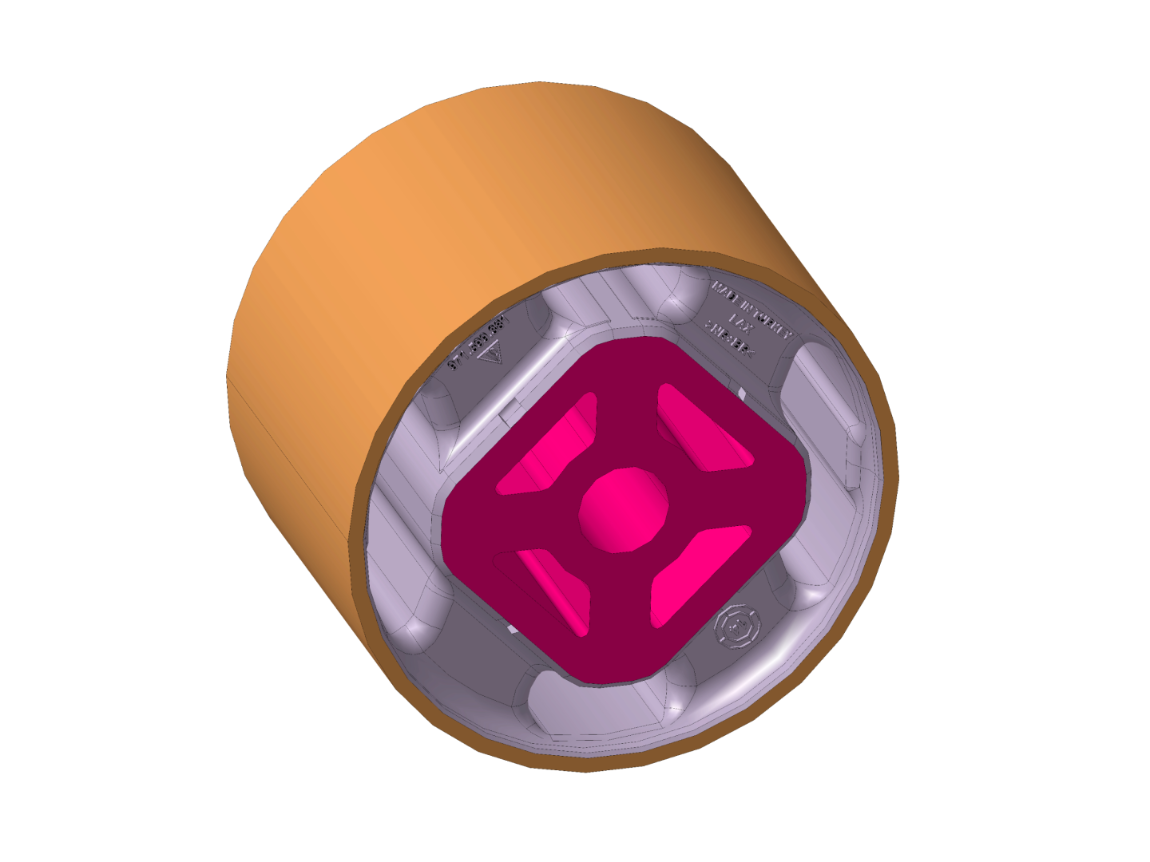

At Angst+Pfister, we’ve reimagined the differential mount for this new era. By combining innovative elastomer compounds with a simplified, integrated design, our engineering team has created a solution that not only tackles high-frequency vibration challenges but also helps OEMs streamline assembly, reduce weight, and cut costs. The result is more than a component upgrade: it’s a step toward the next standard in drivetrain technology.

As electric, hybrid, and autonomous vehicle platforms become more sophisticated, one challenge remains stubbornly persistent: managing noise vibration harshness (NVH) in high-frequency environments. Traditional differential mounts, often based on standard rubber compounds and outdated axial snubbing designs, struggle to keep up.

Especially in electric powertrains, high-frequency excitations lead to hardening of elastomer components. This causes unwanted vibrations to transfer into the chassis, undermining comfort and creating a noticeable disconnect between vehicle performance and driving experience.

Enter Angst+Pfister’s newly engineered differential mount, developed specifically for the demands of modern mobility systems. Developed by our powertrain engineering experts, this mount features:

“Through rethinking rubber, metal, and geometry, we created a solution that challenges the traditional mount design.”

– Kubilay Sancakzade, Engineering Vice General Manager (Interim), Angst+Pfister Advanced Technical Solutions, A.S.

Before vs. After: Measurable Impact at a Glance

| KPI | Standard Mount | New Angst+Pfister Mount | Improvement |

|---|---|---|---|

| HF Hardening Ratio | ~1.7 | ~1.35 | ▼ ~20% |

| Axial Snubbing Design | Separate metal disc | Integrated tube fold | ▼ -1 component |

| Weight per unit | ~500g | ~400g | ▼ ~20% |

| Assembly steps | 2–3 parts | 1 part | Simplified process |

In a recent project, we worked on a high-end electric sports car. The goal was to provide great comfort and to keep noise low during tough driving conditions.

The Angst+Pfister differential mount was selected for this project due to its ability to:

The result: A quieter, more refined driving experience without compromising durability or mechanical protection.

Supply Chain & Production Benefits

The new advanced differential mount with integrated axial snubbing performs better, streamlines manufacturing, and simplifies supply chains:

Why It Matters for Procurement and Engineering

Engineers value the integration of NVH comfort and robust axial protection without added mechanical parts.

Procurement professionals appreciate the reduction in total cost of ownership through weight savings, simplified logistics, and higher production efficiency.

And for both, it supports the broader move toward smart, compact, and integrated drivetrain components: absolutely crucial in the age of electrification and rapid developments in off-highway and agricultural machinery.

Electrification Trends in Agriculture and Construction

Electrification is no longer confined to passenger and commercial vehicles; it is increasingly shaping the future of agriculture and construction machinery as well.

Key developments include:

Battery-electric systems are currently best suited for compact machines, where daily energy needs are manageable and charging strategies can be efficiently implemented. For larger and heavier machinery, electrification still faces technological and economic barriers, though steady progress is being made.

Hydrogen-powered machinery is also gaining traction, with prototypes of hydrogen combustion engines and fuel-cell-based systems signaling potential for broader adoption in the near future.

At the same time, alternative fuels such as hydrotreated vegetable oil (HVO) offer additional pathways to reduce emissions, particularly for use cases like mobile cranes, where life cycle analyses indicate significant CO₂ savings.

The pace of adoption will ultimately depend on overcoming critical challenges around infrastructure, sourcing, and scalability. To deliver meaningful environmental benefits, supply chains for electricity, hydrogen, and alternative fuels must be both sustainable and widely accessible.

Video Q&A

In our latest Q&A session, Daniel Chidley (Senior Engineer Antivibration & Sealing Technology, Angst+Pfister) takes us to the Innovation Park in Zurich to discuss one of the most important topics in the electric mobility era: Noise, Vibration, and Harshness (NVH).

Daniel shares insights into how our engineering team rethought traditional mount design – integrating axial snubbing, optimizing elastomer compounds, and reducing weight – to deliver 20% better vibration isolation and greater efficiency for modern electric vehicles.

Want to know more about our NHV solutions and what’s most important for you as a customer?

Get in touch with our experts for a free consultation and learn how to future-proof your process.

As electrification, automation, and eco-efficiency continue to reshape mobility and machinery, drivetrain components must keep pace. Angst+Pfister’s advanced differential mount demonstrates how smart engineering can deliver real impact: fewer parts, lighter weight, lower costs, and superior NVH control.

For engineers, it means a robust solution that integrates comfort and durability. For procurement teams, it means efficiency across assembly lines and supply chains. And for end users, it means smoother rides, quieter cabins, and greater reliability – whether on the road, in the field, or on the construction site.

In short, this mount is more than an incremental improvement: it’s a reimagined standard for the electric and hybrid era.

Electric and hybrid drivetrains generate significantly more high-frequency excitations compared to internal combustion systems. Traditional differential mounts, typically designed with standard rubber compounds and separate axial snubbers, tend to harden under these frequencies. This hardening transmits unwanted vibrations directly into the chassis, resulting in increased noise, harshness, and a less refined driving experience. As vehicles become quieter overall, these vibrations become even more noticeable, making NVH control a critical design priority.

Our new mount uses an innovative low-hardening elastomer compound combined with a fully integrated axial stopper. This design cuts high-frequency hardening by about 20%, enabling superior isolation of high-frequency vibrations. By preventing these vibrations from reaching the passenger cabin, the mount delivers a smoother, quieter ride – even in high-performance EV applications – while also protecting drivetrain components from premature wear.

We re-engineered the mount’s metal geometry and functional integration to eliminate separate components like snubber discs or washers. This resulted in about 20% weight reduction and a single-piece design that simplifies assembly steps. Fewer components mean faster production, less tooling, and lower inventory complexity, all while improving durability and extending service intervals.

Electrification demands smarter, more compact, and more efficient drivetrain components. Our mount’s lightweight design helps lower overall vehicle weight, supporting energy efficiency and longer range. By simplifying the bill of materials and improving durability, it also reduces material usage, production waste, and logistics overhead. These factors align with the industry’s broader push for eco-efficient, low-emission, and sustainable solutions, especially in emerging markets like electric construction and agricultural machinery.

For engineers, the mount offers integrated NVH comfort and robust axial protection without added mechanical complexity – enabling them to meet strict packaging and performance targets. For procurement teams, it reduces total cost of ownership through fewer parts, lower assembly time, lighter weight, and longer service intervals. Overall, it accelerates production efficiency while helping OEMs achieve both cost and quality targets in next-generation EV and hybrid platforms.

Let’s Talk about Your Project!

Request a Free Consultation and Find a Perfect Solution Customized for you.

Based on our assortment we create and develop an individual solution for your application – or we even develop from scratch a high-performance part for your product to ensure quality & safety. For expert advice and customized solutions tailored to your specific needs,

Let's talk!

Get connected!

Let’s talk about your challenges and how Angst+Pfister can support you.

Your one-stop shop for industrial components

Dive into the extensive range of standard applications in the online shop of APSOparts with great benefits for efficient order processes!