Connect on LinkedIn

Key Takeaways:

Powertrain systems operate under increasingly demanding conditions, especially in sectors such as agriculture, construction, and industrial transportation. These systems require sealing solutions that not only prevent contamination but also contribute to long-term operational efficiency. Angst+Pfister’s advanced cassette seals are engineered to deliver precisely that unparalleled protection and efficiency, ensuring optimal performance even in the most challenging environments. Yet, the question remains which are the right cassette seals for the job and how to choose them.

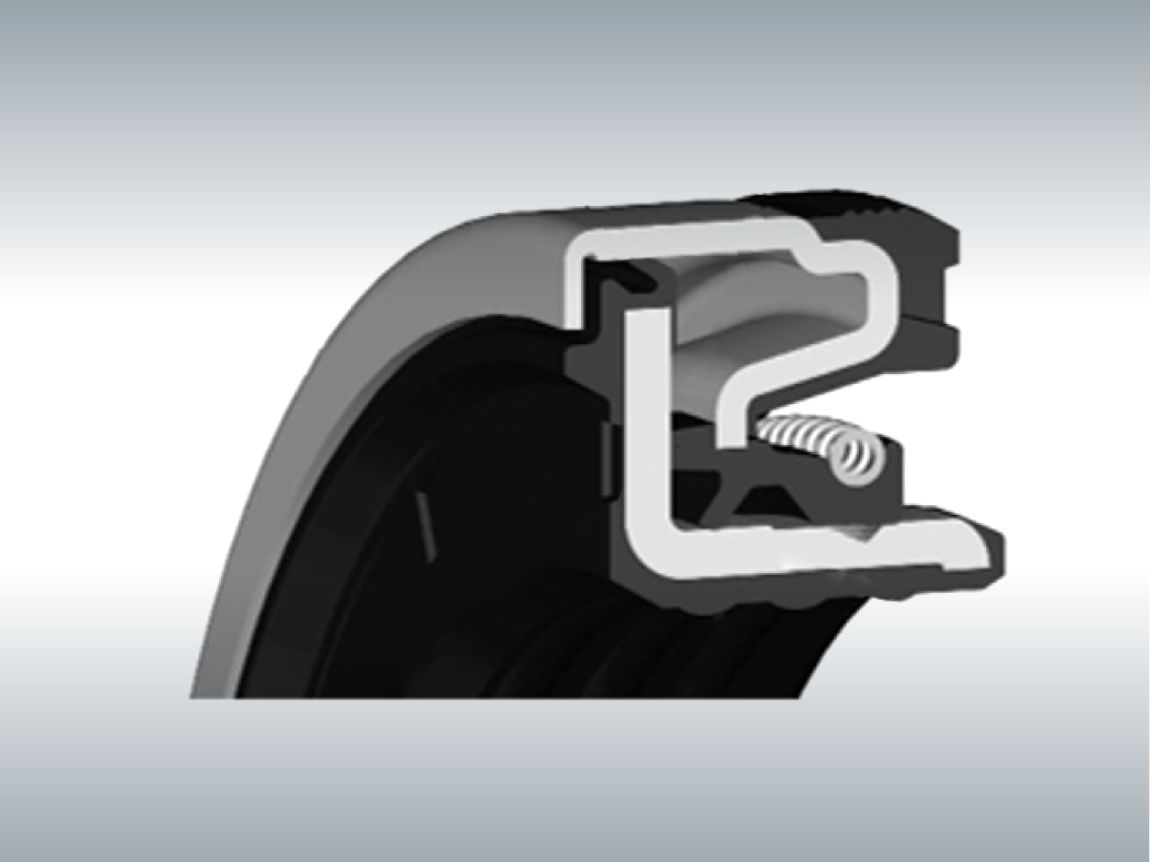

Cassette seals are multi-component radial shaft seals designed to retain lubricants while excluding external contaminants. They are typically used in high-load applications such as gearboxes, wheel hubs, and axles, where effective sealing is critical to performance and reliability.

Unlike conventional sealing solutions, cassette seals incorporate several integrated features that provide comprehensive protection and significantly extend the service life of mechanical components.

Why Modern Powertrain Systems Require Advanced Sealing Solutions

As machinery becomes more powerful and compact, sealing systems must handle faster speeds, and more complex operating environments. In powertrain applications, particularly those in off-highway and industrial settings, seals must deliver:

These requirements necessitate innovative sealing technologies tailored to specific applications.

Challenges in Harsh Operating Environments

Powertrain components are frequently exposed to severe environmental stressors:

Cassette seals must perform reliably across this broad spectrum of use cases while maintaining efficiency and minimizing wear.

Angst+Pfister combines deep industry expertise with advanced design and testing methodologies to produce cassette seals that consistently exceed expectations.

Design Innovations Include:

Finite Element Analysis (FEA) and Real-World Validation

Angst+Pfister cassette seal designs may undergo detailed analysis using Finite Element Analysis (FEA). This allows engineers to simulate performance under operational loads, identify potential failure points, and refine geometries for optimal performance.

Additionally, on purpose thorough lab and field testing ensures each seal meets or exceeds expectations in real-world applications.

Cassette seals from Angst+Pfister are manufactured using carefully selected elastomers and materials tailored to specific application requirements. Commonly used compounds include:

Material compatibility ensures seals perform reliably across a wide range of lubricants and operating conditions.

Custom-Engineered Solutions for Diverse Applications

Angst+Pfister’s cassette seals are not off-the-shelf components. Each design is tailored to meet specific industry requirements, alongside standard designs which can also be produced.

Key application areas include:

Validated Performance Through Precision Testing

Before implementation, all sealing solutions are validated through bench testing and field trials to simulate real operating conditions. These tests measure:

This validation process ensures reliable operation throughout the seal’s service life.

Full Compliance with Industry Standards

Angst+Pfister adheres to strict quality control processes and industry certifications. This includes traceability from raw material sourcing to final inspection, as well as optional end-of-line functional testing. Compliance with automotive and industrial standards reinforces the reliability and safety of each product delivered.

Setting the Benchmark in Sealing Technology

What differentiates Angst+Pfister from other suppliers in the field?

.jpg)

For operators, this translates into reduced total cost of ownership and increased equipment availability.

Sustainable Engineering and Long-Term Value

Angst+Pfister is committed to creating solutions that support long-term sustainability. By improving seal lifespan and minimizing the risk of oil leaks and equipment failures, our cassette seals contribute to more efficient, environmentally responsible machinery.

Conclusion: Sealing the Future of Powertrain Systems

Cassette seals may be small components, but they play a vital role in maintaining the performance and durability of complex powertrain systems. Angst+Pfister’s advanced sealing technologies are built on precision engineering, extensive testing, and a customer-focused approach. Our cassette seals stand out by offering reliable, efficient, and long-lasting protection, even under the most demanding conditions.

With custom designs, high-performance materials, and a commitment to excellence, Angst+Pfister empowers OEMs and system integrators to meet today's challenges and prepare for tomorrow’s innovations.

1. What makes Angst+Pfister’s cassette seals different from standard options?

Angst+Pfister offers tailored solutions based on specific applications, incorporating advanced features like springless lips, hydrodynamic grooves, and enhanced labyrinth paths for superior performance.

2. In which industries are these cassette seals commonly used?

They are widely used in agriculture, construction, transportation, and industrial machinery — anywhere powertrain components require efficient and durable sealing.

3. How are the seals tested for reliability?

Through both laboratory testing and real-world field validation, including simulations of vibration and exposure to contaminants like mud and dust.

4. What materials are used in Angst+Pfister cassette seals?

Depending on the application, materials such as NBR, HNBR, FKM, and ACM are used for optimal chemical, thermal, and mechanical resistance.

5. Can cassette seals be customized for non-standard shafts?

Yes, Angst+Pfister offers customized sleeves and seal geometries for applications involving stainless steel or unhardened shafts.

Let’s Talk about Your Project!

Request a Free Consultation and Find a Perfect Solution Customized for you.

Based on our assortment we create and develop an individual solution for your application – or we even develop from scratch a high-performance part for your product to ensure quality & safety. For expert advice and customized solutions tailored to your specific needs,

Let's talk!

Related Pages and Downloads

Discover our certified, robust solutions for agricultural machinery.

Discover our certified solutions for construction machinery.

.png)

We use CAD and Finite Element Analysis to design, validate, and optimize products efficiently..

.jpg)

We ensure product durability through advanced solution testing and validation.

Catalogue with technical information and basic knowledge for argiculture.

Get connected!

Let’s talk about your challenges and how Angst+Pfister can support you.

Your one-stop shop for industrial components

Dive into the extensive range of standard applications in the online shop of APSOparts with great benefits for efficient order processes!