Key Facts at a Glance

- Compounding as Performance Driver: High-performance sealing solutions are defined at the compound level. That is where polymer chemistry, fillers, and curing systems determine reliability, durability, and compliance.

- End-to-End Control: Angst+Pfister integrates requirement analysis, formulation design, testing, simulation, certification, and industrial production within its global centers of excellence.

- Proven in Practice: Structured compounding methodologies translate into production-ready solutions, as demonstrated by real-world applications such as the Frenlas development project.

At Angst+Pfister, material performance begins at the polymer level. Compounding is more than a process for us: it is the foundation of every high-performance sealing solution we create. By uniting polymer chemistry, process engineering, and regulatory expertise, our teams transform complex application requirements into precisely engineered elastomer materials. Each formulation is developed, tested, and validated within our global centers of excellence to ensure consistent quality, reliability, and compliance across industries. This is where performance truly begins: in the science and engineering of compounding.

Behind every reliable seal lies a hidden discipline – the science of rubber compounding. Long before a product meets pressure, temperature, or chemical exposure, its success begins at the material level. At Angst+Pfister’s centers of excellence, this challenge is mastered daily, combining chemistry, engineering, and regulatory expertise to produce high-performance, compliant materials.

|

Every sealing solution we deliver starts with a compound and ends with measurable reliability. Compounding is the invisible core of everything we do. - Sidika Kavus, Senior Sealing Compound Development Engineer |

Step 1: Understanding the Challenge – Defining Requirements and Compliance Early

Every new compound begins with a conversation. Our engineers immerse themselves in the customer’s application environment, exploring temperatures, pressures, chemical exposures, mechanical stress, and expected service life. For many industries, compliance defines the boundaries even before performance is discussed.

|

While we prioritize exceptional performance, we recognize that compliance is not optional; it is a fundamental requirement that ensures quality and performance in the application. - Vittorino Ballarin, Regulatory Affairs Specialist: |

This early engagement ensures that compounds meet international standards such as FDA, USP Class VI, ISO 10993, or EU 1935/2004. Regional differences in regulations from the U.S. to Europe and Asia are carefully considered, so compounds are globally viable from the start.

Step 2: Designing the Compound – Finding the Perfect Blend

Designing a compound is both science and art. R&D chemists translate technical and regulatory requirements into a precise chemical formulation, selecting base polymers to achieve targeted mechanical, thermal, and chemical performance. The base polymers include EPDM, HNBR, or FFKM, as well as fillers, curing systems, or additives.

|

A compound is like a tailored suit: the polymer is the fabric, the additives are the stitching, and the curing system is the final fit. - Raffaella Villa, Technologist FKM/FFKM |

With over 2,500 proprietary compound recipes, Angst+Pfister leverages decades of experience to innovate while maintaining reproducibility and compliance. Sustainability and future readiness are integral, including the development of PFAS-free alternatives and long-term regulatory resilience.

Step 3: Laboratory Testing and Certification – Where Performance Meets Compliance

Small-scale lab batches allow scientists to validate both performance and certification readiness before production. Physical and chemical testing confirms thermal stability, chemical compatibility, and long-term aging behavior. Rheological properties and curing characteristics are thoroughly investigated to ensure reliable and consistent production.

|

We build compliance into the compound. Not as an afterthought, but as a design principle. - Valerie Thurau, Approvals & Regulatory Affairs Manager |

Testing covers critical certification requirements, ensuring that materials are compliant with the required standards or regulations before external testing, which shortens time-to-market and reduces development risk. With over 2,500 proprietary compound recipes, Angst+Pfister leverages decades of experience to innovate while maintaining reproducibility and compliance. Sustainability and future readiness are integral, including the development of PFAS-free alternatives and long-term regulatory resilience.

Step 4: Simulation and Digital Validation – Ensuring Performance Before Production

Before molds are produced, compound behavior is simulated digitally using Finite Element Analysis (FEA), CAD, and Mold Flow simulations. Engineers predict stress, strain, thermal expansion, and material flow, reducing prototyping cycles and accelerating development.

|

We can predict how a compound will behave long before it’s molded, and that saves months of testing and iteration. - Baris Yilmaz, Sales and Marketing Manager at High Performance Compounds Kaucuk A.S |

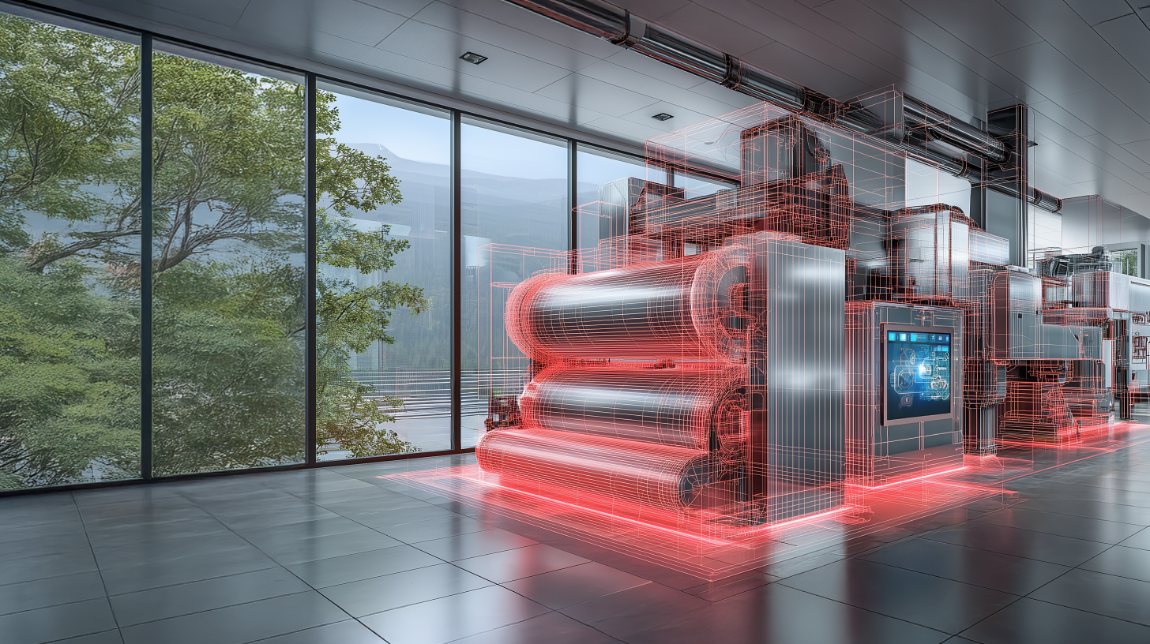

Step 5: From Laboratory to Production – Precision and Traceability

Once validated, compounds move into industrial production using state-of-the-art mixing and molding equipment. All processes are controlled under ISO 9001 and ISO 14001 systems, with full traceability from raw material to finished product.

|

We don’t just manufacture compounds, we manufacture confidence. Every batch is traceable, tested, and compliant with global standards. - Murat Cevher, Plant Manager High Performance Compounds Kaucuk A.S.: |

Vertical integration enables fast lead times, stable quality, and consistent compliance throughout the product lifecycle. The development steps outlined above form a structured development framework for transforming material requirements into production-ready compounds. However, their true value becomes apparent when applied to real applications, where performance targets, dimensional tolerances, and manufacturing constraints must be fulfilled simultaneously.

Step 6: Continuous Improvement and Global Compliance

The journey does not end with production. Angst+Pfister continuously monitors regulatory developments and customer feedback, evolving compounds to meet new global requirements while maintaining performance and reliability.

|

Our customers operate globally, so our compounds are developed to be conform with worldwide standards and regulations. - Sidika Kavus, Senior Sealing Compound Development Engineer |

From PFAS discussions to emerging EU Regulations, the company’s R&D teams evolve materials to meet new industry requirements while maintaining high performance and reliability.

The following application success story illustrates how structured compound development and close technical collaboration enabled precise shrinkage control under fixed tooling conditions, while fully meeting mechanical performance requirements in a safety-critical automotive application.

Turning Challenges into Triumphs: Shrinkage Control Under Fixed Mold Conditions

The Challenge

Frenlas, a leading Turkish manufacturer of passenger car brake rubber components, required an SBR-based rubber compound for a servo diaphragm booster application. This requirement had to be met under a strict boundary condition: the existing mold dimensions could not be modified.

The project initially started from the customer’s established 100 phr SBR formulation, with the first prototypes delivered in September 2025. However, early evaluations showed that the parts did not fully meet key performance requirements, particularly in terms of abrasion resistance, flexibility, and low-temperature behavior.

While increasing the BR content was considered a way to improve mechanical performance, it quickly became clear that higher BR levels would negatively impact shrinkage behavior and exceed dimensional tolerance limits, making mold changes unavoidable, which was not permitted.

The Development Approach

Rather than compromising tooling or performance targets, a structured and iterative compound development approach was applied. Across four development trials, the formulation concept was optimized by:

- Selecting the appropriate BR type and optimizing the BR content to balance mechanical performance and shrinkage behavior

- Adjusting the carbon black system to achieve the required reinforcement while maintaining dimensional stability

- Optimizing filler loading and introducing mineral additives to improve dimensional stability and support shrinkage control

Close technical collaboration with Frenlas throughout the process ensured transparency, alignment on performance limits, and fast decision-making.

The Result

The final compound successfully met all mechanical and functional requirements while keeping shrinkage fully within tolerance, without any change to mold dimensions or tuning. The formulation demonstrated reliable abrasion resistance, flexibility, and cold-temperature performance and proved suitable for stable series production.

Following a minor commercial adjustment, the compound was approved. First samples were delivered in September 2025, and the first official order was received in December 2025.

Business Impact

- Initial project value: ~150 k€

- Gross profit: 27%

- SOP: Q1/2026

- Growth potential: >250 k€ per year with additional product sizes

Q&A Video

To complement the topics discussed in this article, Angst+Pfister has recorded a dedicated Q&A video in which compounding and application experts address the most common technical questions related to high-performance rubber compounds.

The video provides additional background on how material requirements are translated into compound design, how trade-offs between performance, processability, and compliance are managed, and which factors are critical for achieving stable series production. Practical examples from real development projects further illustrate the role of compounding as a key enabler for reliable sealing solutions.

Watch the Q&A video to gain firsthand insights from our specialists and deepen your understanding of how compounding expertise turns material science into application success.

Conclusion

From polymer selection to finished seal, Angst+Pfister controls every step of the compounding journey: design, testing, certification, and production. The result is materials that perform, comply, endure, and empower the world’s most demanding applications.

If your application demands extreme performance and absolute reliability, contact the compounding experts at Angst+Pfister. Together, we will design a material that does more than meet expectations: it redefines them.

Frequently Asked Questions

What is rubber compounding, and why is it important for sealing performance?

Rubber compounding defines the material properties of a seal by combining polymers, fillers, curing systems, and additives. It directly determines reliability, durability, chemical resistance, and long-term performance in demanding applications.

When should rubber compounding be addressed during product development?

Compounding should be considered at the earliest project stage. Early definition of operating conditions, regulatory requirements, and manufacturing constraints ensures performance and compliance are built into the material from the start.

How does Angst+Pfister ensure compliance with global regulations?

Regulatory requirements such as FDA, USP Class VI, ISO 10993, or EU 1935/2004 are integrated into compound design and validated through internal testing before series production, ensuring global compliance and certification readiness.

Can rubber compound performance be improved without changing existing molds?

Yes. Through targeted compound optimization, it is possible to improve mechanical performance and dimensional stability without modifying mold dimensions, as demonstrated in the Frenlas automotive application case.

How is consistent quality ensured in the series production of rubber compounds?

Angst+Pfister produces compounds under ISO 9001 and ISO 14001 certified processes with full material traceability, ensuring reproducible quality and reliable performance throughout the product lifecycle.

Get connected!

Let’s talk about your challenges and how Angst+Pfister can support you.

Your one-stop shop for industrial components

Dive into the extensive range of standard applications in the online shop of APSOparts with great benefits for efficient order processes!