Connect on LinkedIn

Key Takeaways:

In today’s manufacturing environment, sustainability and technical performance must go hand in hand. Engineers and OEMs are looking for reliable, high-performing materials that also align with environmental goals. Angst+Pfister offers 100% bio-based engineering plastics - developed without fossil-based resources and compatible with stringent industry standards.

Fossil-based plastics dominate industrial applications due to their durability and versatility. But industries such as food processing, agriculture, and machine building face increasing pressure to reduce their carbon footprint and adopt sustainable materials. Many “green” plastics on the market rely on mass balance production, require complex certifications, and are only partially bio-based.

Angst+Pfister’s bio-based polymers are made from 100% renewable feedstock using dedicated, segregated reactors - no mass balancing involved. This guarantees:

Available bio-based materials include:

All materials are machinable, FDA and EU certified, and electrically insulating.

Performance Comparison

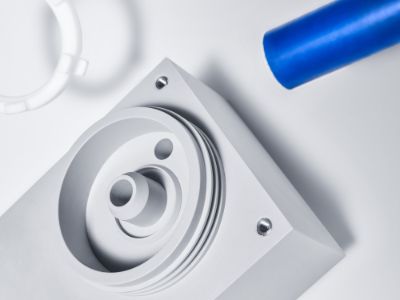

Bio-Based PA6G in Food Dosing Valves

| Property | Standard PA6G | Bio-Based PA6G | Improvement |

|---|---|---|---|

| Tensile Strength at yield | 75 MPa | 80 MPa | +7% |

| Impact Strength (Charpy) | 3 kJ/m2 | 4 kJ/m2 | +33% |

| Estimated CO₂ Footprint | 100% fossil | 100% renewable | -88% |

The Result

Improved mechanical strength, higher durability, and significantly lower environmental impact.

“We’ve developed a material that performs like traditional engineering plastics but with a drastically reduced CO₂ footprint. This is measurable sustainability - not just marketing.”

Alessandro D., Product Manager Engineering Plastics Technology

Q: What is a bio-based plastic?

A: A plastic made from renewable, plant-based feedstock instead of fossil fuels.

Q: Are bio-based materials food-safe?

A: Yes, Angst+Pfister’s materials are FDA and EU compliant for food contact.

More questions are being answered in the Q&A video session with Product Manager Engineering Plastics Technology, Alessandro D’Ettorre.

Are you interessted to get a free consultiaton on our bio-based plastics solution? Then contact us!

Conclusion: Proven Materials for a Sustainable Future

Angst+Pfister’s 100% bio-based engineering plastics allow OEMs and engineers to meet sustainability targets, reduce operational CO₂ emissions, and maintain high-performance standards. Whether it’s food processing, mechanical engineering, or agri-tech, these materials deliver.

Let’s Talk about Your Project!

Request a Free Consultation and Find a Perfect Solution Customized for you.

Based on our assortment we create and develop an individual solution for your application – or we even develop from scratch a high-performance part for your product to ensure quality & safety. For expert advice and customized solutions tailored to your specific needs,

Let's talk!

Related Pages

At Angst+Pfister, we stay ahead of the curve in Engineering Plastics Technology. We offer a comprehensive range of services for practically every applica ...

Discover our certified solutions for the Food & Beverage industry.

Get connected!

Let’s talk about your challenges and how Angst+Pfister can support you.

Your one-stop shop for industrial components

Dive into the extensive range of standard applications in the online shop of APSOparts with great benefits for efficient order processes!