Welcome to the Angst+Pfister Solutions Hub – our engineering blog and gateway to expert insights on mechanical and industrial engineering.

Angst+Pfister specializes in customized industrial engineering solutions for high-performance sealing, antivibration, and fluid handling solutions. With over a century of experience, we empower engineers across industries to solve complex challenges through technical expertise and innovative materials.

The Solutions Hub is our knowledge platform for engineers and technical professionals. Here, you’ll find deep-dive content on the latest industry topics—from PFAS-free innovations and regulatory updates to smart elastomers and sustainable solutions such as bio-based plastics.

Through applied engineering case studies, regulatory briefings, and real-world examples, the Solutions Hub offers practical knowledge and proven strategies to help engineers and technical professionals navigate complex challenges. Check out our "Trending this Month – Solutions Hub Highlights" and see what’s driving innovation across industries or browse all of our blog posts.

Stay up to date on trending industry topics and expert insights with our newsletter.

Rubber compounding transforms material science into reliable, compliant high-performance sealing solutions.

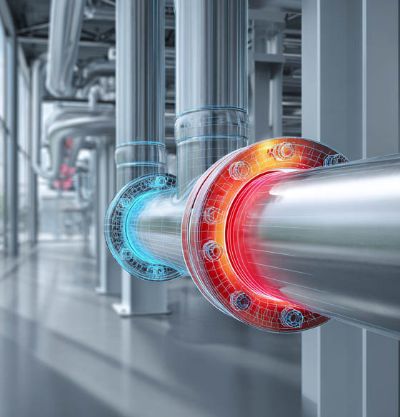

How evolast® FFKM Keeps It Under Control

Smarter Differential Mounts for Electric and Hybrid Vehicles

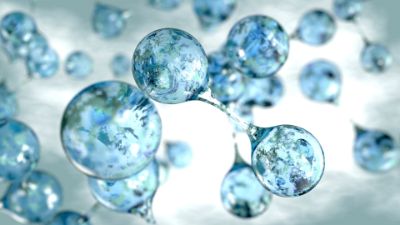

Reliable hydrogen sealing ensures safety, prevents leaks, and extends system lifetime.

Durable, compliant hoses optimized for safe, efficient CIP/SIP cleaning.

evolast® FFKM prevents seal failures with extreme resistance and full compliance.

Discover how plastic can reduce CO₂ emission without performance compromise.

Discover how cassette seals for powertrain applications ensure durability and efficiency.

Smart elastomers enable real-time monitoring, predictive maintenance, and efficiency improvements.

Operate LNG systems safely and efficiently - with stainless steel corrugated hoses.

The proposed EU regulation on PFAS may impact polymer sealing materials.

Navigating the challenges of safe, cost-effective plastic components in the food and beverage industry.

Angst+Pfister drives effective solutions in meeting the fire regulation EN45545.

New global PFAS regulations push for PFAS-free materials, urging collaboration with trusted suppliers

The choice of the optimum material guarantees unlimited coffee enjoyment.

HITEC® DW EPDM elastomer meets and exceeds upcoming drinking water standards.

PERTEC® UP EPDM compound meets global food contact regulations, ensuring safety.

Angst+Pfister rigorously tests elastomers for hydrogen applications, ensuring suitability for future energy solutions.

We make it work!

Just contact us and We will get back to you as quickly as possible!

Stay up-to-date!

Sign up for our newsletter today and receive our newest updates on products and latest industry trends!